U-AK elastomer seal for cast iron bell-end sewage pipes for the discharge of water from buildings. DN 50-200 mm

Application:

- Sealing of spigot and socket joints between cast iron pipes in gravity sewage systems.

- Sealing of PVC – cast iron joints.

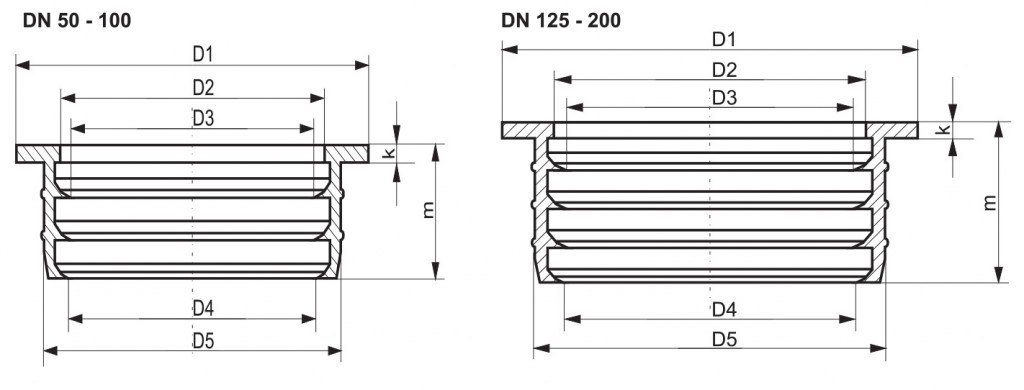

The U-AK seal has the structure and shape of a flanged bushing that is rounded on the outside and has protrusions on the inside. The seal is made of injection moulded SEBS thermoplastic elastomer (TPE).

|

|

| Selection chart | ||||||||

|---|---|---|---|---|---|---|---|---|

| Diameter DN | D1 [mm] | D2 [mm] | D3 [mm] | D4 [mm] | D5 [mm] | m [mm] | k [mm] | weight [g] |

| 50 | 90 | 60 | 50 | 50 | 72 | 54 | 4 | 85 |

| 70 | 110 | 80 | 70 | 70 | 92 | 54 | 4 | 110 |

| 100 | 145 | 112 | 102 | 106 | 126 | 64 | 6 | 200 |

| 125 | 172 | 137 | 125 | 125 | 150 | 70 | 6 | 240 |

| 150 | 200 | 162 | 150 | 155 | 176 | 80 | 6 | 365 |

| 200 | 250 | 208 | 195 | 202 | 217 | 80 | 6 | 490 |

Advantages of U-AK seals over traditional joints:

- Greatly speeds up installation works

- Easy to assemble and disassemble

- Further use of seal possible after disassembly

- User-friendly installation – elimination of cumbersome application of tar rope

- Joint is ready immediately after installation

- Guarantee of tightness of seal

- Elastic joint – after assembly of joint, the angles between pipes and fittings can still be slightly altered

|

|

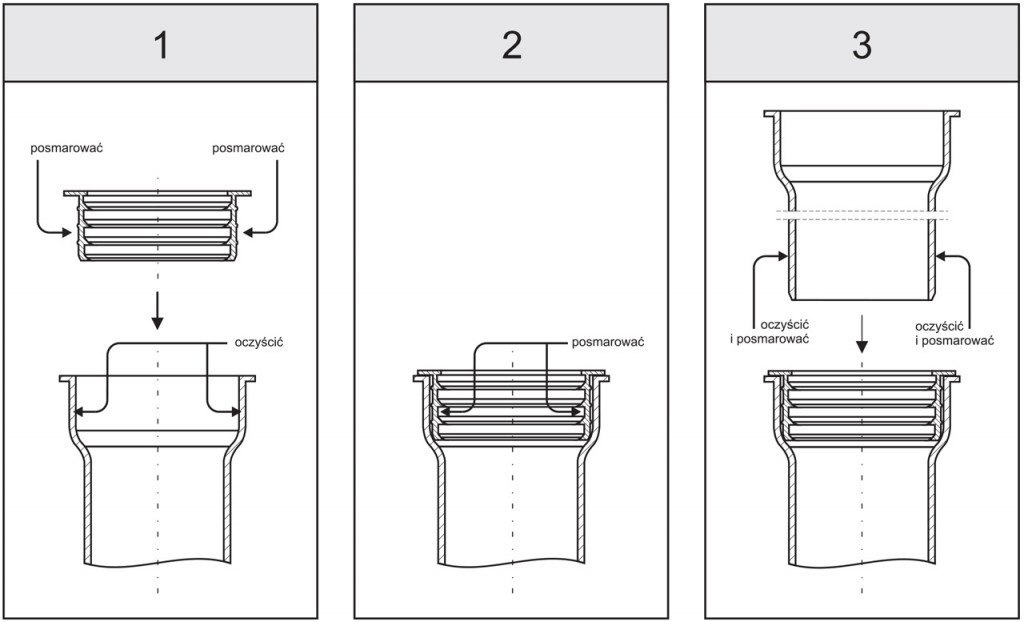

Joints made using U-AK type seals are very easy to assemble. The seal must be introduced into the bell end of pipe/fitting so that the seal flange presses against the end of the bell. The plain end of the pipe/fitting and the internal part of the seal should be covered with a lubricant (such as washing liquid or other) and then the pipe/fitting is introduced into the seal in alignment with a line marked beforehand on the plain end that indicates the depth of introduction of pipe/fitting into the seal. In the event of the presence of flashing or burrs on the plain end or inside the bell end of the pipe fitting that could damage the seal or impair installation, such flashing or burrs should be removed. A slanted edge of the plain end of pipe/fitting to be introduced into the seal will greatly facilitate installation.